Concrete Cooling Solutions

Product Details:

Concrete Cooling Solutions Price And Quantity

- 1000000 INR/Unit

- 1 Unit

Concrete Cooling Solutions Trade Information

- MUMBAI

- 4 Unit Per Month

- 4-6 Week

- SKID Mounted in CKD condition

- All India

Product Description

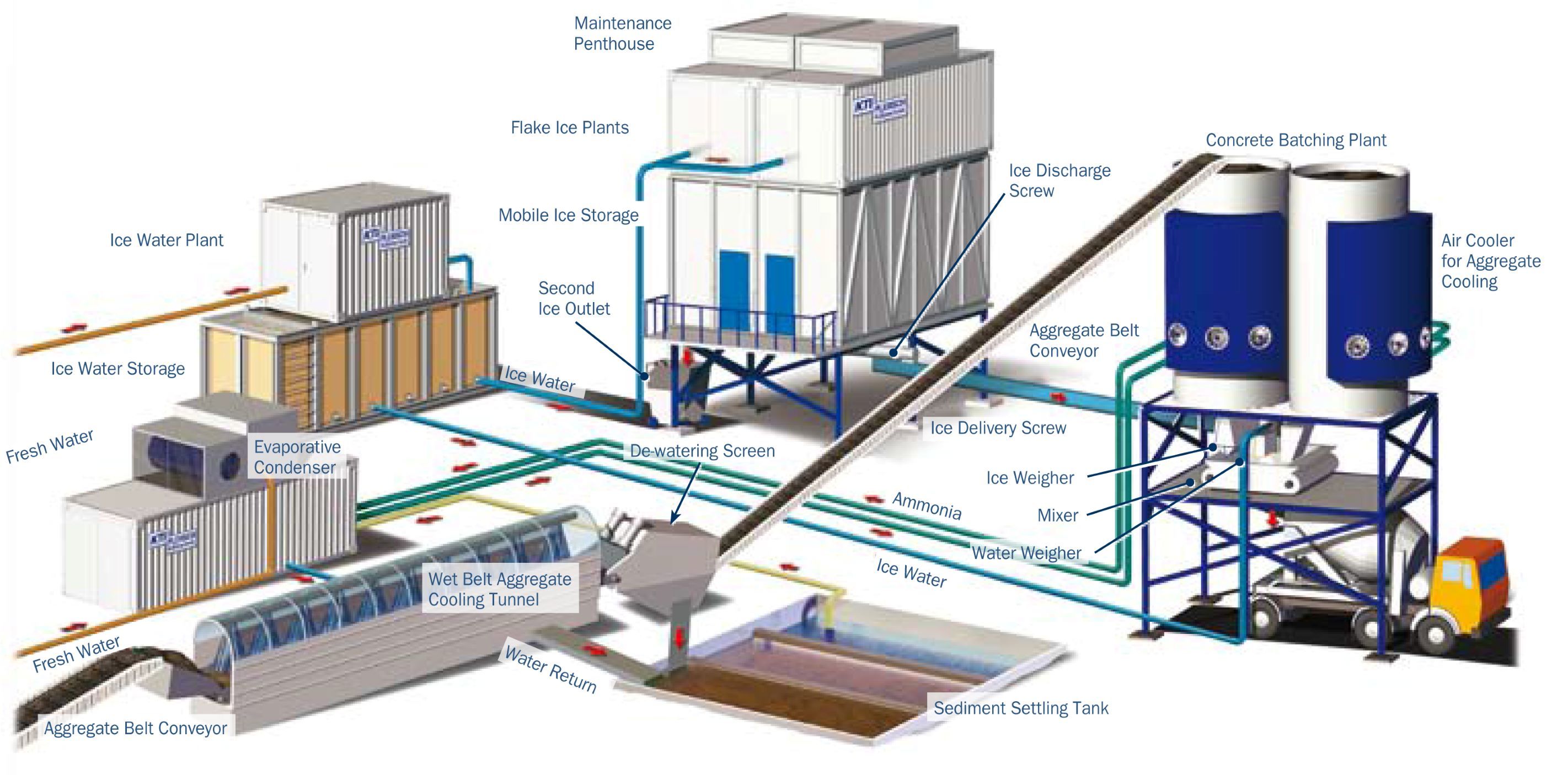

Concrete Cooling Solution in Mumbai and India. All around the world, temperature-controlled concrete is used to build large-sized sets and to fill in the large scaled bases of high buildings, dams, and other constructions. The heat of hydration developed within the concrete during the process increases the temperature of the concrete to around 40 to 60C depending on the initial temperature of pouring.

This causes an increase in volume and release of water vapor resulting in cracks in the cured concrete, compromising the structural integrity of the structure. In order to prevent the damage, the initial filling temperature of the concrete should be low enough to ensure that the maximum temperature reached during the operations does not exceed the value set by the design units. Using 0 C to + 1 C cold water is an effective pre-cooling method.

We have the following Concrete Cooling Solution in Mumbai and India for all your Concrete Cooling requirements:

- Ice Bank Tanks - Give Water at 0 C to + 1 C

- Chilling Plants/ Vertical Chillers - Give Water at 3 C to 4 C

- Flake Ice Plants - Produce small flakes of 1.5mm - 2mm thick flakes facilitating immediate melting in the batching Plant

- Flake Ice Storage/ Levelling/ Dispensing Plant

We can offer Concrete Cooling Solution in Mumbai and India in Ammonia, Halocarbon/Freon and other new generation green gases as a refrigerant.

Some of our Clients in the Concrete Cooling Sector are as follows:

- Patel Engineering limited

- Gammon India Limited

- L & T

- Lafarge Cement

- Nuvoco Vistas Limited

- Afcon Limited

- Essar Limited

Technical Specifications

Refrigerant | Ammonia/Halocarbon/Freon/R-22/ R 404A |

Capacity | 5 Ton to 40 Ton (Single Plant) |

Usage/Application | Industrial |

Brand | Singhsons |

Material | MS, SS, GI |

Type | Concrete Cooling Plant |

Temperature Range | 0-4 Deg C |

Other Products in 'Concrete Cooling Solutions' category

We want Bulk Inquires.

|

SINGHSONS REFRIGERATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese